Blog

Would you like to learn more about the world of Cognac? Here you can answer your questions!

Childrens

Sub Category 1

Odio ut pretium ligula quam Vestibulum consequat convallis fringilla Vestibulum nulla. Accumsan morbi tristique auctor. At risus pretium urna tortor metus fringilla interdum mauris tempor congue

Landscape and heritage

Nurseries

|

This profession experienced a consequent growth at the time of the phylloxera crisis, before the vine multiplied by simple cuttings without any particular technique.

Figures: In 2020 it is: 880 professionals registered to control the timber and vine plants, including 461 producers of plants and 234 traders. In Nouvelle-Aquitaine, 22% of the professionals and 15% of the mother vines are located in Nouvelle-Aquitaine. The market for vine nursery growers is worth around €300 million in sales, 230 million plants in 2019 (including around 60 million just in Nouvelle-Aquitaine). Nearly 15% of exports amounted to 13 million euros in 2020. , that is, the production is essentially sold on the French market. Recently, the FFPV launched its common brand «Vitipep’s», guaranteeing a 100% French origin.

The nursery farmer is a winegrower who specializes in grafting. It is the professional who will give birth to the vines. He will perform a graft (omega graft), that is to say he will assemble a rootstock and a graft. These two elements will heal together (called «stratification») and then will be planted in the nursery which will give the first roots..

There are two main sectors in the vineyard nursery: - The producers of vines mother feet, they will produce wood that will be used for grafting, there are about 25 varieties of rootstocks that will adapt to the soil in which they will be planted. - Growers of grafted-welded plants who will ensure their marketing

Seedlings will be planted from February or in small pots in greenhouses to cover the current year’s planting demand (from May to November)either in an open-field nursery that will root for a year and then be dug up and resold as bare root, which will then be planted from February to April.

The wood and vine plants are certified by the organization FranceAgriMer, allowing, thus, to eliminate possible contamination, and to fight against diseases such as flavescence dorée or black wood. The mother vines will be subjected to periodic tests (introduced since 1995) sanitary, every 10 years, thus allowing to have healthy and therefore certified equipment. In the case of identification of possible contamination, the plot will be immediately quarantined for two years and its plant material will either be destroyed or treated with hot water (for 45 minutes) at approximately 50°C.

In short, vine nurserymen are essential professionals in the production of wines and thus spirits, and they are professionals who are upstream of the production, without them no vines, no wines, no spirits, no cognacs.

If you want to discover this profession in video:

|

350.jpg)

Vineyards and know-how

Cooperage, an essential know-how for the Cognac ?

|

The history of the barrels Historically, the barrels have been used in Europe for more than 2000 years and would have been invented by the Celts and probably the Gauls. Originally the barrels were designed for the preservation of goods, but also for transport by their rounded forms allowing them to be rolled. To date, they are mainly used for the rearing of wines and waters of life. |

|

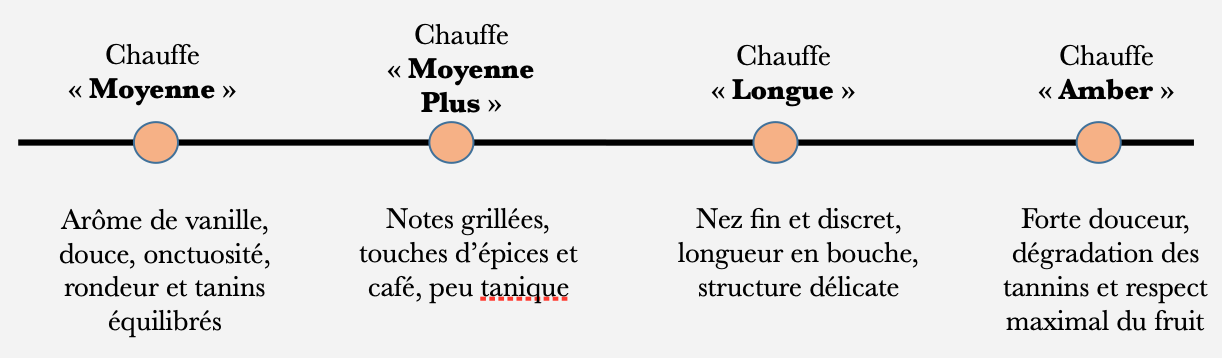

The barrels in a few figures In a few figures, Cognac cooperage is about 660,000 barrels produced in France in 2019, 1900 professionals, 150 French cooperages. Finally, nearly 70% of the production of French oak barrels are exported internationally and mainly to Australia, Spain, the United States and Italy. |

|

The composition of the barrels

The barrels used for the aging of the cognac are made only of oak wood, this one comes mainly from the forests of Allier and Limousin. There are two types of oak: coarse-grained oak (called «pedunculate oak») or fine-grained oak (called «sessile oak»), depending on the uses one wishes to make of it. These two oaks have different characteristics that can impact the aging of cognac. The coarse-grained oak (the kernels corresponding to the width of the rings) has more tannins than the fine-grained oak which can bring wood and coconut aromas (these aromas resulting from the «methyloctalactones»), or cloves (due to «eugenol»).

To shape its barrels, the cooper’s mission (formerly known as the “Barrel Cutter”) is to select the pieces of wood (called the “Staves”) that will compose them. Once selected, they will be air-dried for a minimum of 2 years. |

|

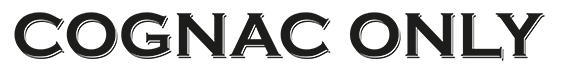

Burning, a stage impacting the future eau-de-vie that will be aged After the choice of the wood in the barrels, an essential step, which will impact the aging cognac, is the burning of the barrels (also known as "bousinage"). This step makes it possible to transform the wood macromolecules (lignin, cellulose and hemicellulose) into aromatic molecules which will allow a better impregnation of the aromas by the eau-de-vie. It should be noted that each heating level has its own aromatic profile. |

|

The characteristics of the barrels When the manufacturing stage is completed, the drums are marketed. If in Burgundy and Bordeaux the average volume of barrels is 225/230 liters, in cognac the average volume is between 350 and 500 liters. The size of the barrels is thought according to the ration volume/surface/contact. In summary, this means that the higher the volume, the more the ratio increases which causes a slower aging, on the contrary, for the barrels with a lower volume the aging will be faster. The barrels were designed to have a long life (from twenty-five to forty years). |

|

Cooper a craft with a certain future ? To be a cooper is to acquire a know-how worthy of «haute couture». The French cooperage is the world market leader, both for the raw material (the quality of the wood of its forests) and for the expertise of professionals. Bringing together nearly 2,000 co-workers, it is a craft of the future as essential in the wine sector, where the growth of activity generates a constant need for new professionals. It is a profession that can be enriched by several experiences: manufacture, repair of barrels, supply for export, customer relations, it is an evolutionary and enriching profession. To learn more: |

350.jpg)

Drinking and tasting

How is glass, useful for the packaging of Cognac is made ?

|

The history of traditional know-how Glass blowing is a technique invented in the 1st century BC in the Middle East. Since antiquity, workshops in Poitou-Charentes will transform glass imported from the Middle East. The development of glassware in Poitou-Charentes corresponds to the widespread packaging of cognac in bottles at the end of the 19th century. Between 1892 and 1898, Claude Boucher, master glassmaker, developed a semi-automatic machine for the blowing of glass (machine that bears his name), the father of modern machines to blow, these will be generalized in France and internationally. It should be noted that since 2019, the Glass Art professions have been included in the inventory of intangible cultural heritage in France. Today, there are nearly 576 glass and crystal factories in France, nearly 40 «Meilleur Ouvrier de France» professionals in French companies. Glass is obtained from sand with quartz (called silica), which will be heated to its melting point, that is to say to reach 1,300°. The glass maker will take a part of the mixture (called «glass paste», the parison) with a hollow cane of about 1, 40 meters (formerly called a “crack”) and will shape it by stretching it. This mixture will be worked with a torch, or more rarely, by hand. After having worked the material, the object will be cooked in an oven and then left to cool in the air in order to be cut and decorate. |

|

The glass blower is the first professional to act to design the objects. It will shape the glass through blowing, stretching or twisting. He is going to “pick” a molten glass ball and come and work on it. So it is he who will form the glass, he can also color it by rolling the glass ball in powders, grains or glass plates colored with metal oxides (cobalt, copper, iron, gold). |

|

Then comes the role of the tailor on crystals (or glass decorator) who will come to cut geographical forms (a predefined pattern) on crystal or glass pieces. He’s going to work with something out of the glass blower’s oven. He will first polish the glass to remove the cutting edges, then he will mark the location of the decoration by digging it with grinding wheels and then he will cut his motif. Finally, he will finish his work by smoothing everything to restore the sparkle to the glass. |

|

In the wine estate, it is possible for houses to order custom bottles. For this, a mould will be designed to give a quality and personalized bottle. For this, designers, glass manufacturers, technicians will collaborate together to obtain the mold in which will be cast future customized glass bottles. |

|

Working in the glass? The glass blower is an essential profession in the field of cognac, because it allows to have quality bottles, necessary for the packaging of cognac. Their know-how is recognized, both in the shaping of objects and in the preparation of glass dough. To access this profession, there is a CAP glassblower, but also a BAC professional arts and crafts and finally a Diploma of crafts architectural decoration, option glass and crystal arts. As for the crystal tailor, master in the art of glass decoration, last step to transform bottles into decorative objects, this profession is accessible from the CAP to a +4 bin in engraving. |