Cooperage, an essential know-how for cognac ?

Find here de know-how and the particularities of the cooper trade.

Cooperage, an essential know-how for the Cognac ?

|

The history of the barrels Historically, the barrels have been used in Europe for more than 2000 years and would have been invented by the Celts and probably the Gauls. Originally the barrels were designed for the preservation of goods, but also for transport by their rounded forms allowing them to be rolled. To date, they are mainly used for the rearing of wines and waters of life. |

|

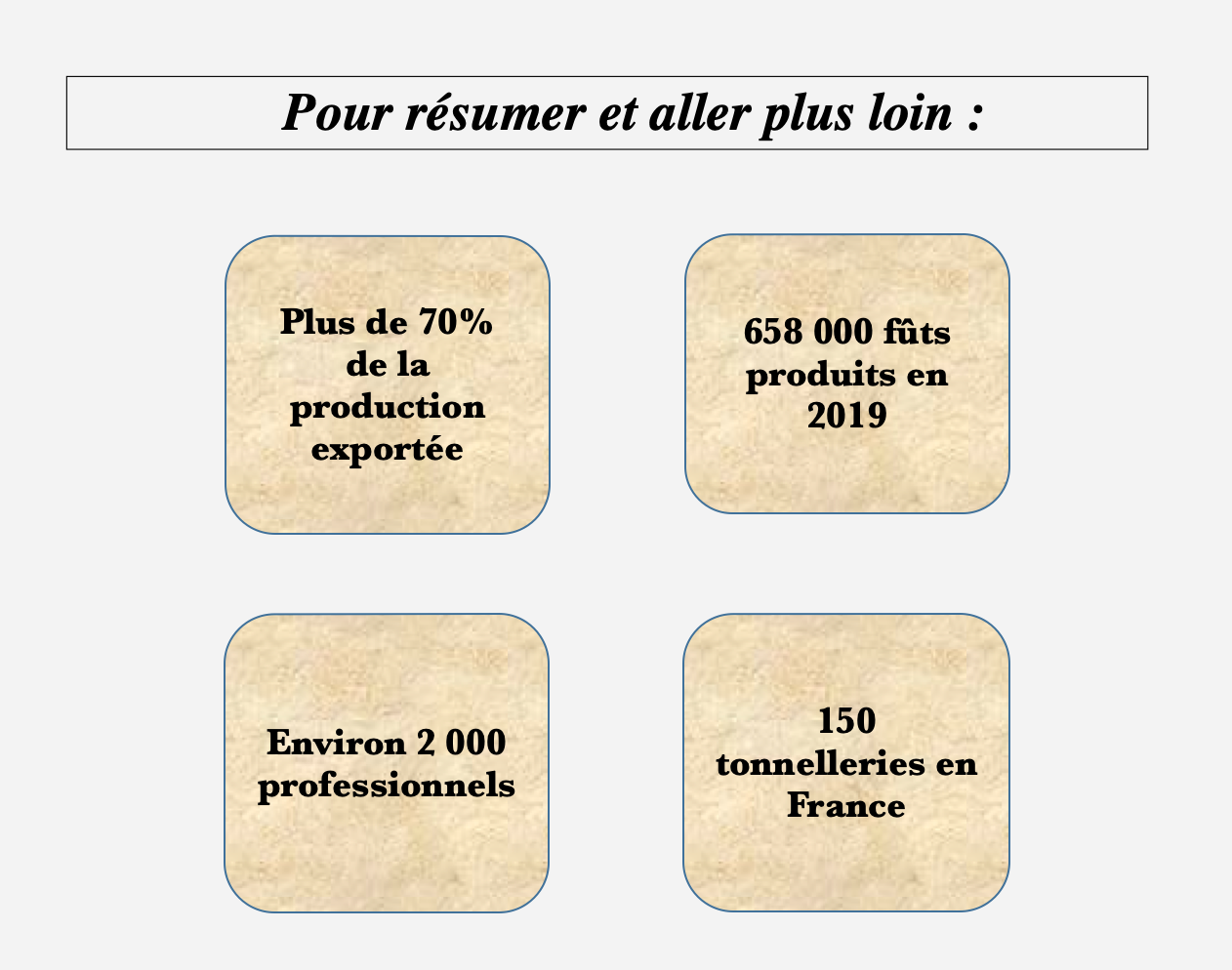

The barrels in a few figures In a few figures, Cognac cooperage is about 660,000 barrels produced in France in 2019, 1900 professionals, 150 French cooperages. Finally, nearly 70% of the production of French oak barrels are exported internationally and mainly to Australia, Spain, the United States and Italy. |

|

The composition of the barrels

The barrels used for the aging of the cognac are made only of oak wood, this one comes mainly from the forests of Allier and Limousin. There are two types of oak: coarse-grained oak (called «pedunculate oak») or fine-grained oak (called «sessile oak»), depending on the uses one wishes to make of it. These two oaks have different characteristics that can impact the aging of cognac. The coarse-grained oak (the kernels corresponding to the width of the rings) has more tannins than the fine-grained oak which can bring wood and coconut aromas (these aromas resulting from the «methyloctalactones»), or cloves (due to «eugenol»).

To shape its barrels, the cooper’s mission (formerly known as the “Barrel Cutter”) is to select the pieces of wood (called the “Staves”) that will compose them. Once selected, they will be air-dried for a minimum of 2 years. |

|

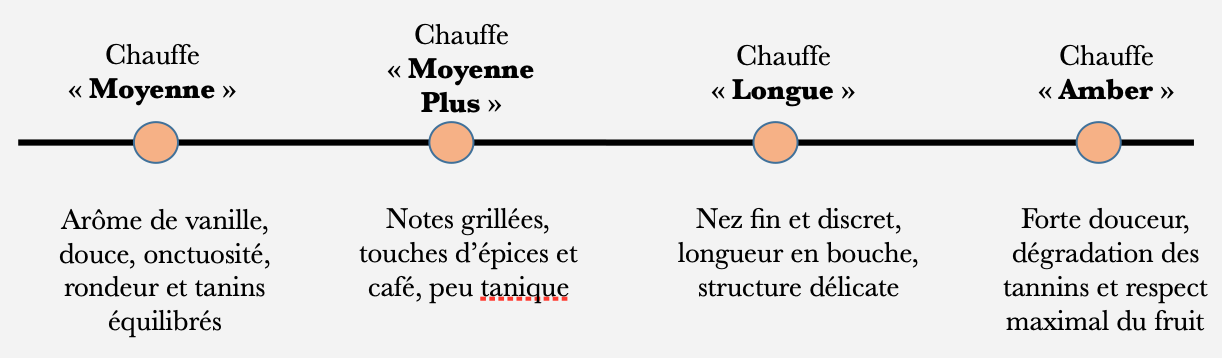

Burning, a stage impacting the future eau-de-vie that will be aged After the choice of the wood in the barrels, an essential step, which will impact the aging cognac, is the burning of the barrels (also known as "bousinage"). This step makes it possible to transform the wood macromolecules (lignin, cellulose and hemicellulose) into aromatic molecules which will allow a better impregnation of the aromas by the eau-de-vie. It should be noted that each heating level has its own aromatic profile. |

|

The characteristics of the barrels When the manufacturing stage is completed, the drums are marketed. If in Burgundy and Bordeaux the average volume of barrels is 225/230 liters, in cognac the average volume is between 350 and 500 liters. The size of the barrels is thought according to the ration volume/surface/contact. In summary, this means that the higher the volume, the more the ratio increases which causes a slower aging, on the contrary, for the barrels with a lower volume the aging will be faster. The barrels were designed to have a long life (from twenty-five to forty years). |

|

Cooper a craft with a certain future ? To be a cooper is to acquire a know-how worthy of «haute couture». The French cooperage is the world market leader, both for the raw material (the quality of the wood of its forests) and for the expertise of professionals. Bringing together nearly 2,000 co-workers, it is a craft of the future as essential in the wine sector, where the growth of activity generates a constant need for new professionals. It is a profession that can be enriched by several experiences: manufacture, repair of barrels, supply for export, customer relations, it is an evolutionary and enriching profession. To learn more: |

Comments

No comment at this time!

Leave your comment